#Turbine Oil Cleaning System

Explore tagged Tumblr posts

Text

⚙️ Turbine Oil Cleaning System India – Efficient Filtration & Purification by OilFilterMachineIndia.com

OilFilterMachineIndia.com is a leading manufacturer and exporter of high-performance Turbine Oil Cleaning Systems in India, offering advanced solutions to remove sludge, varnish, water, and particle contamination from turbine oils.

Our systems are trusted across thermal power plants, hydropower stations, and turbine-driven industrial operations. Whether you need a portable turbine oil cleaning system or a mobile turbine oil filtration unit, we deliver robust, energy-efficient, and field-proven equipment.

🛢️ Our Key Offerings:

Precision-based Turbine Oil Cleaning System India

High-speed Turbine Oil Purification System India

Heavy-duty Turbine Oil Filtration Equipment

Real-time Turbine Oil Contamination Removal

Cost-effective Turbine Oil Cleaning Solutions for long-term use

Expert-built Turbine Oil Treatment India machines

Efficient Turbine Oil Cleaning India with moisture and particle control

Modular & skid-mounted Portable Turbine Oil Cleaning Systems

Field-ready Mobile Turbine Oil Filtration machines

End-to-end Industrial Turbine Oil Cleaning technologies

🌍 Why Choose Our Turbine Oil Cleaning Solutions?

Removes water, sludge, varnish, oxidation by-products, and particulates

Increases oil life and turbine efficiency

Reduces wear and failure of bearings, seals, and gears

Easy to operate, portable, and quick to deploy

Trusted by major power and energy clients in India and abroad

Our systems are designed using advanced vacuum dehydration, filtration, and centrifuging techniques to meet ISO 4406 cleanliness standards.

📍 Proudly Made in India | Serving Globally 🔗 Explore our complete range: https://oilfiltermachineindia.com/turbine-oil-cleaning-systems.html

#Turbine Oil Cleaning System#Turbine Oil Cleaning System India#Turbine Oil Purification System India#Turbine Oil Filtration#Turbine Oil Filtration Equipment#Turbine Oil Contamination Removal#Turbine Oil Cleaning Solutions#Turbine Oil Treatment India#Efficient Turbine Oil Cleaning India#Portable Turbine Oil Cleaning Systems#Mobile Turbine Oil Filtration#Industrial Turbine Oil Cleaning

0 notes

Text

Why Transformer Dry-Out Systems Are the Future of Power Maintenance

Introduction

The Challenges of Moisture in Transformers

Moisture is one of the most significant threats to transformer health. It degrades the insulating properties of transformer oil and solid insulation, leading to several issues, including:

Decreased Dielectric Strength: Excess moisture lowers the ability of the transformer oil and insulation to withstand electrical stress.

Accelerated Aging: Moisture accelerates cellulose degradation, shortening the lifespan of the transformer.

Increased Risk of Failures: Water content in insulation leads to overheating, arcing, and even catastrophic transformer failures.

Traditional moisture management practices often involve oil replacement or reactive maintenance, both of which are costly and time-consuming. This is where Transformer Dry-Out Systems step in as a game-changer.

What Are Transformer Dry-Out Systems?

Transformer Dry-Out Systems are advanced equipment designed to remove moisture from transformer oil and solid insulation without requiring a shutdown. These systems use innovative technologies such as vacuum dehydration, molecular sieve filtration, or thermodynamic processes to extract water from the system efficiently. Unlike traditional methods, dry-out systems provide a continuous, in-service solution, enabling real-time moisture control.

Benefits of Transformer Dry-Out Systems

Oil testing includes a variety of analytical procedures designed to evaluate the condition and properties of insulating oil in transformers. These tests can be categorized into the following key areas:

Enhanced Transformer Reliability Moisture reduction improves the dielectric strength of transformer oil, ensuring stable performance under varying load conditions. With dry-out systems, the risk of dielectric breakdown is significantly reduced, enhancing overall system reliability.

Extended Transformer Lifespan By removing moisture from solid insulation, transformer dry-out systems slow down the aging process of cellulose insulation. This extends the operational life of transformers, maximizing return on investment.

Cost Savings on Maintenance Transformer failures are costly, often requiring significant repairs or complete replacements. Dry-out systems prevent such failures by maintaining optimal moisture levels, reducing the need for reactive maintenance and costly downtime.

Real-Time Monitoring and Control Many modern dry-out systems are equipped with sensors and IoT-enabled technologies that provide real-time data on moisture levels, temperature, and oil quality. This allows for predictive maintenance strategies and improved decision-making.

Environmental Sustainability Replacing transformer oil generates waste and requires additional resources. Dry-out systems reduce the frequency of oil replacements, contributing to a more sustainable maintenance approach.

Key Technologies in Transformer Dry-Out Systems

1.Vacuum Dehydration

Vacuum dehydration is a proven method for removing dissolved and free water from transformer oil. By subjecting the oil to a high vacuum, water is evaporated at low temperatures, ensuring the preservation of the oil's chemical properties.

2.Molecular Sieve Filtration

Molecular sieves are specialized materials with microporous structures that adsorb moisture from transformer oil. This method is highly effective in maintaining oil purity and preventing re-contamination.

3.Thermodynamic Separation

This advanced technique leverages temperature and pressure differentials to separate water molecules from oil. Thermodynamic separation is particularly effective in high-capacity transformers.

Applications of Transformer Dry-Out Systems

1. Power Generation Plants

In power generation facilities, transformers operate under high loads and are critical for uninterrupted power supply. Dry-out systems ensure these transformers remain moisture-free, reducing the likelihood of outages.

2. Industrial Power Distribution

Industries rely heavily on transformers to power operations. Dry-out systems enable industries to maintain uninterrupted production schedules by preventing transformer failures.

3. Renewable Energy Systems

Renewable energy projects, such as wind and solar farms, depend on transformers for efficient power distribution. Transformer dry-out systems enhance the reliability and efficiency of these setups.

4. Utility Networks

In utility networks, where transformers are spread across vast geographical areas, dry-out systems provide an efficient and scalable solution for moisture management.

Minimac Systems’ Transformer Dry-Out Solutions

At Minimac Systems, we specialize in providing state-of-the-art solutions that redefine transformer maintenance. Our Transformer Dry-Out Systems are designed with cutting-edge technology to ensure effective and efficient moisture removal without the need for downtime.

Key Features of Minimac Transformer Dry-Out Systems

High-Efficiency Moisture Removal:Our systems are equipped with advanced vacuum dehydration and thermodynamic separation technologies for unparalleled moisture extraction.

Compact Design:Minimac dry-out systems are portable, allowing easy deployment across sites, even in remote areas.

Real-Time Monitoring:Integrated sensors and IoT compatibility provide actionable data for predictive maintenance strategies.

User-Friendly Interface:Our systems are designed for intuitive operation, requiring minimal training for on-site staff.

Environmentally Conscious:With minimal oil wastage, our systems align with global sustainability goals.

Why Choose Minimac Systems?

Proven Expertise:With years of experience in transformer maintenance solutions, Minimac Systems is a trusted name in the industry.

Custom Solutions:We tailor our systems to meet the unique requirements of every client, ensuring maximum effectiveness.

Reliable Support: From installation to routine maintenance, our team offers comprehensive support services to ensure uninterrupted operations.

Comprehensive Maintenance and Support Services

Implementing Transformer Dry-Out Systems is only the beginning of effective transformer maintenance. To maximize the performance and lifespan of these systems, dedicated maintenance and support services play a critical role.

1. Regular Performance Assessments

Scheduled inspections ensure that the dry-out system continues to operate at peak efficiency. These checks identify any wear, blockages, or system inefficiencies before they escalate into significant issues.

2. System Calibration and Upgrades

Advanced systems may require periodic calibration to ensure accurate moisture detection and removal. Upgrades to software and hardware ensure the system remains compatible with modern operational demands.

3. Emergency Troubleshooting and Repairs

Expert service teams provide immediate assistance during unexpected malfunctions. This minimizes downtime and prevents prolonged exposure to moisture that could damage the transformer.

4. Comprehensive Training Programs

Operators and maintenance teams benefit from hands-on training programs, enabling them to effectively manage the dry-out system and respond to anomalies promptly.

5. Customized Maintenance Plans

Tailored service plans take into account the specific operational environment and transformer requirements, ensuring optimized performance and prolonged equipment life. By integrating routine maintenance with reliable support services, transformer dry-out systems deliver unmatched value and dependability for the power sector.

Why Transformer Dry-Out Systems Are the Future

As the power industry evolves to meet growing demands, reliability and efficiency have become non-negotiable. Transformer dry-out systems align perfectly with these requirements. Here's why they represent the future of power maintenance: 1. Proactive Maintenance

The shift from reactive to proactive maintenance is a significant trend in the power sector. Dry-out systems enable utilities to address moisture issues before they escalate into costly failures.

2. Digital Integration

Modern dry-out systems are compatible with digital monitoring tools and SCADA (Supervisory Control and Data Acquisition) systems. This integration supports data-driven maintenance and enhances operational efficiency.

3. Regulatory Compliance

Governments and regulatory bodies are emphasizing sustainability and operational efficiency in power systems. By minimizing waste and improving transformer performance, dry-out systems help organizations comply with these standards.

4. Cost-Effectiveness

With increasing pressure to reduce operational costs, utilities and industries are adopting solutions that offer long-term savings. Dry-out systems fit this need by reducing maintenance costs and extending equipment life.

Conclusion

Transformer Dry-Out Systems are transforming the landscape of power maintenance by offering a reliable, efficient, and sustainable solution to moisture management. As the industry moves toward more proactive and data-driven maintenance strategies, these systems will play a pivotal role in ensuring the longevity and reliability of transformers. Incorporating comprehensive maintenance and support services further enhances the value of these systems, ensuring they deliver optimal performance throughout their lifecycle. Adopting a transformer dry-out system is not just an investment in equipment—it's an investment in the future of power infrastructure.

Are you ready to future-proof your transformer maintenance strategy?

Choose Minimac Systems’ Transformer Dry-Out Solutions for superior reliability, cost savings, and operational efficiency.

Click here to learn more about Minimac Systems Transformer Dry-Out System: https://www.minimacsystems.com/transformer-dryout-system

Contact us today to learn how the Minimac Transformer Dry-Out System can transform your lubrication practices and ensure the success of your operations!

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#chemical cleaning flushing#chemical flushing#tofs#elc#bdv#testing kit#oil#oil analysis#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power industry#metal#mining

0 notes

Text

"The man who has called climate change a “hoax” also can be expected to wreak havoc on federal agencies central to understanding, and combating, climate change. But plenty of climate action would be very difficult for a second Trump administration to unravel, and the 47th president won’t be able to stop the inevitable economy-wide shift from fossil fuels to renewables.

“This is bad for the climate, full stop,” said Gernot Wagner, a climate economist at the Columbia Business School. “That said, this will be yet another wall that never gets built. Fundamental market forces are at play.”

A core irony of climate change is that markets incentivized the wide-scale burning of fossil fuels beginning in the Industrial Revolution, creating the mess humanity is mired in, and now those markets are driving a renewables revolution that will help fix it. Coal, oil, and gas are commodities whose prices fluctuate. As natural resources that humans pull from the ground, there’s really no improving on them — engineers can’t engineer new versions of coal.

By contrast, solar panels, wind turbines, and appliances like induction stoves only get better — more efficient and cheaper — with time. Energy experts believe solar power, the price of which fell 90 percent between 2010 and 2020, will continue to proliferate across the landscape. (Last year, the United States added three times as much solar capacity as natural gas.) Heat pumps now outsell gas furnaces in the U.S., due in part to government incentives. Last year, Maine announced it had reached its goal of installing 100,000 heat pumps two years ahead of schedule, in part thanks to state rebates. So if the Trump administration cut off the funding for heat pumps that the IRA provides, states could pick up the slack.

Local utilities are also finding novel ways to use heat pumps. Over in Massachusetts, for example, the utility Eversource Energy is experimenting with “networked geothermal,” in which the homes within a given neighborhood tap into water pumped from underground. Heat pumps use that water to heat or cool a space, which is vastly more efficient than burning natural gas. Eversource and two dozen other utilities, representing about half of the country’s natural gas customers, have formed a coalition to deploy more networked geothermal systems.

Beyond being more efficient, green tech is simply cheaper to adopt. Consider Texas, which long ago divorced its electrical grid from the national grid so it could skirt federal regulation. The Lone Star State is the nation’s biggest oil and gas producer, but it gets 40 percent of its total energy from carbon-free sources. “Texas has the most solar and wind of any state, not because Republicans in Texas love renewables, but because it’s the cheapest form of electricity there,” said Zeke Hausfather, a research scientist at Berkeley Earth, a climate research nonprofit. The next top three states for producing wind power — Iowa, Oklahoma, and Kansas — are red, too.

State regulators are also pressuring utilities to slash emissions, further driving the adoption of wind and solar power. As part of California’s goal of decarbonizing its power by 2045, the state increased battery storage by 757 percent between 2019 and 2023. Even electric cars and electric school buses can provide backup power for the grid. That allows utilities to load up on bountiful solar energy during the day, then drain those batteries at night — essential for weaning off fossil fuel power plants. Trump could slap tariffs on imported solar panels and thereby increase their price, but that would likely boost domestic manufacturing of those panels, helping the fledgling photovoltaic manufacturing industry in red states like Georgia and Texas.

The irony of Biden’s signature climate bill is states that overwhelmingly support Trump are some of the largest recipients of its funding. That means tampering with the IRA could land a Trump administration in political peril even with Republican control of the Senate, if not Congress. In addition to providing incentives to households (last year alone, 3.4 million American families claimed more than $8 billion in tax credits for home energy improvements), the legislation has so far resulted in $150 billion of new investment in the green economy since it was passed in 2022, boosting the manufacturing of technologies like batteries and solar panels. According to Atlas Public Policy, a research group, that could eventually create 160,000 jobs. “Something like 66 percent of all of the spending in the IRA has gone to red states,” Hausfather said. “There certainly is a contingency in the Republican party now that’s going to support keeping some of those subsidies around.”

Before Biden’s climate legislation passed, much more progress was happening at a state and local level. New York, for instance, set a goal to reduce its greenhouse gas emissions from 1990 levels by 40 percent by 2030, and 85 percent by 2050. Colorado, too, is aiming to slash emissions by at least 90 percent by 2050. The automaker Stellantis has signed an agreement with the state of California promising to meet the state’s zero-emissions vehicle mandate even if a judicial or federal action overturns it. It then sells those same cars in other states.

“State governments are going to be the clearest counterbalance to the direction that Donald Trump will take the country on environmental policy,” said Thad Kousser, co-director of the Yankelovich Center for Social Science Research at the University of California, San Diego. “California and the states that ally with it are going to try to adhere to tighter standards if the Trump administration lowers national standards.”

[Note: One of the obscure but great things about how emissions regulations/markets work in the US is that automakers generally all follow California's emissions standards, and those standards are substantially higher than federal standards. Source]

Last week, 62 percent of Washington state voters soundly rejected a ballot initiative seeking to repeal a landmark law that raised funds to fight climate change. “Donald Trump’s going to learn something that our opponents in our initiative battle learned: Once people have a benefit, you can’t take it away,” Washington Governor Jay Inslee said in a press call Friday. “He is going to lose in his efforts to repeal the Inflation Reduction Act, because governors, mayors of both parties, are going to say, ‘This belongs to me, and you’re not going to get your grubby hands on it.’”

Even without federal funding, states regularly embark on their own large-scale projects to adapt to climate change. California voters, for instance, just overwhelmingly approved a $10 billion bond to fund water, climate, and wildfire prevention projects. “That will be an example,” said Saharnaz Mirzazad, executive director of the U.S. branch of ICLEI-Local Governments for Sustainability. “You can use that on a state level or local level to have [more of] these types of bonds. You can help build some infrastructure that is more resilient.”

Urban areas, too, have been major drivers of climate action: In 2021, 130 U.S. cities signed a U.N.-backed pledge to accelerate their decarbonization. “Having an unsupportive federal government, to say the least, will be not helpful,” said David Miller, managing director at the Centre for Urban Climate Policy and Economy at C40, a global network of mayors fighting climate change. “It doesn’t mean at all that climate action will stop. It won’t, and we’ve already seen that twice in recent U.S. history, when Republican administrations pulled out of international agreements. Cities step to the fore.”

And not in isolation, because mayors talk: Cities share information about how to write legislation, such as laws that reduce carbon emissions in buildings and ensure that new developments are connected to public transportation. They transform their food systems to grow more crops locally, providing jobs and reducing emissions associated with shipping produce from afar. “If anything,” Miller said, “having to push against an administration, like that we imagine is coming, will redouble the efforts to push at the local level.”

Federal funding — like how the U.S. Forest Service has been handing out $1.5 billion for planting trees in urban areas, made possible by the IRA — might dry up for many local projects, but city governments, community groups, and philanthropies will still be there. “You picture a web, and we’re taking scissors or a machete or something, and chopping one part of that web out,” said Elizabeth Sawin, the director of the Multisolving Institute, a Washington, D.C.-based nonprofit that promotes climate solutions. “There’s this resilience of having all these layers of partners.”

All told, climate progress has been unfolding on so many fronts for so many years — often without enough support from the federal government — that it will persist regardless of who occupies the White House. “This too shall pass, and hopefully we will be in a more favorable policy environment in four years,” Hausfather said. “In the meantime, we’ll have to keep trying to make clean energy cheap and hope that it wins on its merits.”"

-via Grist, November 11, 2024. A timely reminder.

#climate change#climate action#climate anxiety#climate hope#united states#us politics#donald trump#fuck trump#inflation reduction act#clean energy#solar power#wind power#renewables#good news#hope

2K notes

·

View notes

Text

Donald Trump’s latest executive order blocking new offshore wind leases and stalling clean energy projects is an intentional effort to prop up Big Oil at the expense of our economy, our jobs, and our planet.

This is economic sabotage. The U.S. clean energy sector employs millions of workers, and offshore wind alone could create hundreds of thousands of new jobs. But Trump would rather kill these opportunities to keep America chained to outdated, polluting fossil fuels. His actions will raise consumer energy costs and drag us backward just as the world accelerates toward renewables.

Congress has already allocated billions for clean energy investments. Trump’s order is a blatant attempt to withhold funding that has already been approved, an illegal power grab designed to stall progress and appease his fossil fuel donors.

We need real leadership. Congress must fully fund renewable energy, work to block Trump’s executive order, and conduct oversight to stop his administration’s pro-fossil fuel sabotage.

Demand Congress overturn Trump’s attack on clean energy, and protect critical investments in wind and solar energy now.

The climate crisis is accelerating, and the last thing we need is a deliberate effort to slow down clean energy progress. Blocking offshore wind development and stalling renewable projects will only deepen our dependence on fossil fuels, driving up emissions at a time when we need to be cutting them.

We have the technology and resources to build a cleaner, more resilient energy system. Investing in wind and solar can reduce pollution, create stable jobs, and help prevent the worst impacts of climate change.

But Trump’s policies put corporate interests ahead of public health, environmental stability, and our economic future.

Congress must take immediate action to protect clean energy investments, prevent the administration from withholding critical funding, and push back against policies that keep us locked into outdated, polluting energy systems.

The climate fight cannot wait. Demand Congress defend renewable energy and ensure a sustainable future by adding your name now.

Together, we can stop Trump’s fossil fuel takeover and protect clean energy.

@upontheshelfreviews

@greenwingspino

@one-time-i-dreamt

@tenaflyviper

@akron-squirrel

@ifihadaworldofmyown

@justice-for-jacob-marley

@voicetalentbrendan

@thebigdeepcheatsy

@what-is-my-aesthetic

@ravenlynclemens

@thegreatallie

@writerofweird

@bogleech

@anon-lephant

@mentally-quiet-spycrab

@therealjacksepticeye

7 notes

·

View notes

Text

Essential Auxiliary Machinery on Ship

1. Generators

Generators are the heartbeat of a ship’s electrical system. They provide electrical power for various onboard systems, such as lighting, navigation equipment, communication systems, and HVAC (Heating, Ventilation, and Air Conditioning). Depending on the ship’s size and power requirements, multiple generators may be installed to ensure redundancy and continuous power supply during extended voyages.

2. Boilers

Boilers are essential for producing steam, which is utilized for various purposes on board. Steam is used for heating fuel oil and other fluids, running steam turbines for power generation, and operating various machinery and auxiliary machinery equipment, such as steam-driven pumps and winches.

3. Air Compressors

Air compressors generate compressed air used to power pneumatic tools, such as wrenches and chipping hammers, and operate pneumatic control systems. They also provide compressed air for starting main engines and auxiliary engines.

4. Purifiers

Fuel and lube oil purifiers play a critical role in maintaining the quality of fuels and lubricants used onboard. These machines remove impurities, water, and solids from fuel and oil, ensuring smooth engine operation and prolonging the life of critical machinery.

5. Refrigeration and Air Conditioning Systems

Refrigeration and air conditioning systems are vital for maintaining the temperature of provisions, perishable cargo, and living spaces. These systems use refrigerants and cooling coils to control temperature, humidity, and air quality throughout the ship.

6. Ballast Water Treatment Systems

To maintain stability and maneuverability, ships require ballast water to be pumped in or out as cargo is loaded or unloaded. Ballast water treatment systems are responsible for purifying and treating the ballast water to prevent the spread of invasive species and maintain marine ecosystem health.

7. Sewage Treatment Plants

Sewage treatment plants are responsible for processing and treating wastewater generated onboard. They help ensure that treated effluent meets international environmental standards before it is discharged into the sea.

8. Bilge Water Separators

Bilge water separators remove oil and other contaminants from the bilge water, a mix of seawater and oil that collects in the lower parts of the ship. The clean water is then discharged, while the separated oil is collected for proper disposal.

9. Incinerators

Incinerators are used to burn solid waste generated onboard, such as paper, cardboard, and non-recyclable plastics. Proper incineration reduces waste volume and ensures compliance with environmental regulations.

10. Water Makers

Water makers use reverse osmosis or distillation processes to convert seawater into potable water for drinking, cooking, and various onboard applications. They are especially vital for long voyages where access to freshwater sources may be limited.

Conclusion

The auxiliary machinery found on ships plays a crucial role in maintaining the vessel’s efficiency, safety, and comfort during journeys at sea. From power generation to waste management and water purification, each system contributes to the smooth operation and sustainability of modern ships. The continuous advancement of auxiliary machinery technology further enhances the capabilities and environmental performance of ships, making them safer, greener, and more reliable for maritime transportation across the globe.

#generator parts#ship machinery parts#navigation equipment#Auxiliary Machinery Equipment#Ship Machinery Parts#Auxiliary Machinery#Generator Parts#Automation#Navigation#pumps#automation systems

2 notes

·

View notes

Text

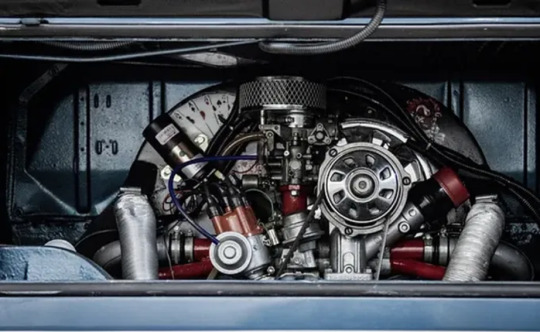

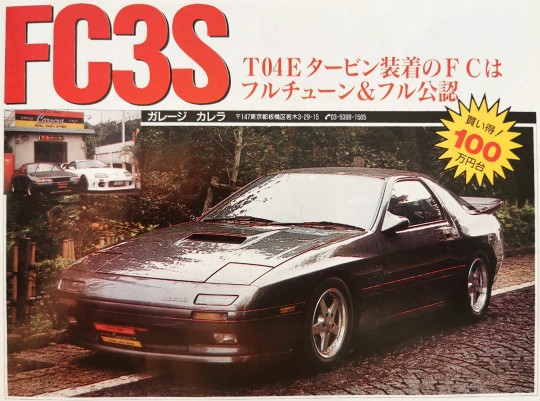

FC3S

T04E turbine equipped FC is fully tuned & fully certified

garage Carrera

3-29-15 Wakagi, Itabashi-ku, Tokyo 147 03-5398-1565

Now is the time to buy FC3S. There are many cars available in the market and it is easy to choose. If you miss this period, the rest will be good.

There will only be less and less, and prices will go up accordingly. This garage Carrera FC3S has been properly tuned, and the price is 1.55 million yen. For the tune menu, I replaced the turbine with T04E , added 7200x2 to the original computer, and controlled the fuel with AIC. The intercooler is an Amemiya two-layer type, the waste gate is a TRUST racing type, and the muffler is a 90 mid-range sports type.

Although it is a 1st year model, this is all there is to it.

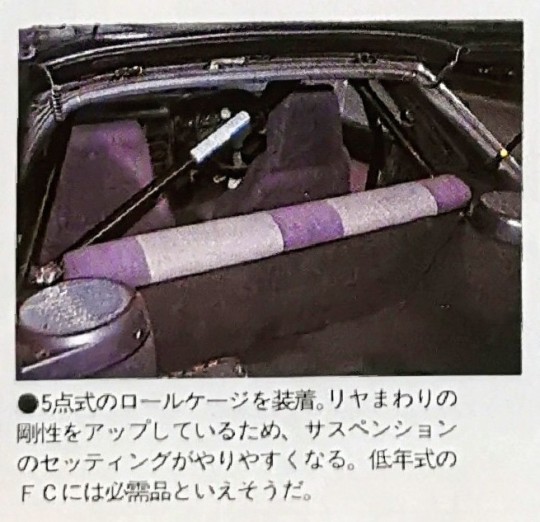

It's been done, fully certified, and 1.55 million yen is cheap. Surprisingly, the mileage is only 48,000km, so I'm sure the engine has a lot more to offer. The only exterior features include Amemiya's Type 1 rear spoiler and Yours' aero mirror. The suspension has Esprit. It has a casual appearance and gives off an atmosphere dedicated to driving. In fact, seeing that the 5-point system was installed in the roll cage, the previous owner must have been very picky about running. The FC's body rigidity was low, especially in this part with the large hatch. This twisting of the body is the reason why even if you keep your feet steady, you still feel ambiguous near the limit. The purpose of building a roll cage is to increase safety in the event of a fall, as well as increase body rigidity. Even a 5-point system is quite effective. Driving on the circuit in the same condition as purchased

I think I can make a good time If you look at the actual 5-point system installed in the roll

PIC CAPTIONS

●Neatly laid out white meters are lined up inside the glove box. The interior is so clean that it's hard to believe it's a very old FC.

●Equipped with a 5-point roll cage. The increased rigidity around the rear makes suspension settings easier. It seems to be a must-have item for younger model FCs.

●The T04E turbine does not have peaky output characteristics, so it is easy to handle. The low sound quality that comes from the sports muffler gives off an atmosphere of great power.

INFO BOX

Savannah RX-7

1999 model inspected December 8th

Mileage 48,000km 1,550,000 yen

Tune data: T04E Turbine

Trust Racing wastegate

Amemiya 2-layer intercooler

Original computer

AIC

additional injector 720cc×2 EVC

OS twin

Blow-off valve

Tower bar

Earl's Oil cooler

Yours aero mirror

17 notes

·

View notes

Text

Control Valve Market Size, Share, Scope and Trends for 2023-2033

The Control Valve Market in United States is expected to undergo a Compound Annual Growth Rate (CAGR) of 7.1% from 2023 to 2033. The uptick in control valve sales within the country can be attributed to the presence of control valve manufacturers and a growing base of end users. Moreover, the robust industrial infrastructure in the United States is poised to drive increased adoption of control valves.

The worldwide control valve market size is estimated to be worth $13 billion in 2023, and it is projected to achieve a value of $23.3 billion by the end of 2033, with a consistent annual growth rate (CAGR) of 6% over the decade under consideration.

Download a Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=439

In the ever-evolving landscape of industrial automation and process control, control valves play a pivotal role in ensuring precise regulation of fluid flow, temperature, and pressure within various systems. Recent trends indicate that the global control valve market is witnessing steady expansion across key industries, fueled by a growing emphasis on efficiency, sustainability, and technological advancements.

Control Valve Market Key Sectors

Oil and Gas Industry

The oil and gas sector has always been at the forefront of adopting advanced technologies to optimize production and reduce operational costs. Control valves have become indispensable tools in this industry, ensuring the precise control of flow rates, pressure, and temperature in various processes. With the growing demand for oil and gas, the control valve market continues to expand to meet the requirements of exploration, production, and refining operations.

Power Generation

The power generation industry is experiencing a transformation with an increasing focus on renewable energy sources and energy efficiency. Control valves are integral in power plants, where they help manage the flow of steam, water, and other fluids, ensuring the safe and efficient operation of turbines and boilers. The need for more advanced control valves to enhance energy efficiency and reduce emissions is driving market expansion in this sector.

Chemical Industry

The chemical industry relies on precise control of various processes to maintain product quality and safety. Control valves are essential for handling corrosive and hazardous chemicals, making them critical for the industry's success. As chemical manufacturing continues to grow globally, the control valve market is expanding to meet the sector's demands.

Water and Wastewater Treatment

The necessity for clean water and effective wastewater treatment is paramount. Control valves are vital in water distribution and treatment plants to regulate water flow and maintain water quality. With increasing urbanization and the need for sustainable water management, the control valve market in this sector is on a steady growth trajectory.

Competitive Landscape

Prominent control valve manufacturers are making substantial investments in research and development to pioneer innovative solutions, all the while adhering to stringent safety regulations. These industry leaders consistently pursue strategic initiatives like rigorous quality control, adherence to product standards, forging strategic partnerships, and optimizing supply chain management to fortify their foothold in the market. The overarching objective is to expand their influence at both domestic and international levels, thereby offering their clientele a broader spectrum of product offerings.

For instance,

In November 2019, Bürkert introduced a redundancy block featuring valves and pressure switches tailored for applications with elevated safety prerequisites.

Key Segments of Control Valve Industry Research

By Actuation Technology :

Manual

Pneumatic

Hydraulic

Electric

By Valve Type :

Ball

Butterfly

Globe

Plug

Others

By Application :

Metal & Mining

Pulp & Paper

Power Generation

Oil & Gas

Chemicals

Food & Beverages

Automotive

Pharmaceuticals

Water & Wastewater Management

Others

By Region :

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Get Customization on this Report: https://www.factmr.com/connectus/sample?flag=RC&rep_id=439

The control valve market is witnessing steady expansion across key industries due to its fundamental role in ensuring precise and efficient control of various processes. As industries continue to prioritize efficiency, sustainability, and advanced technologies, the demand for control valves is expected to grow further. This trend is a testament to the adaptability and resilience of the control valve market, which remains a vital component in the world of industrial automation and process control.

Contact: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

I

have ave three master one in chemistry ( explosives) one in Wildlife mgt ( wildlife economics) and one on Metaphysics ( energy healing) 18 years as an intelligence investigator/ analyst and profiler..I learnt idiots scoff mainly because the brainwashed by mainstream media bullshit ..and font even know it ..studied at Tavistock and worked for 5412 ..

this it proganda only 0,1% of co2 is anthropogenic Forest are increasing because of Co2 without coz youbwoyld oxidase and die Oxygen destroys everything .

The proximity to the sun cause the poles to move the poles 135 km in a decade This caused polar shift Ice melted but glaciers are multiplying faster ever before

Petrol.coal and petrochemical cone from bacteria and are not fossil fuels you can make ceued in days in a factory..

plastic cam beaten by bacteria in weeks

all the people running the climate change agenda at IPPC are petrochemicals tycoons including the Director Tgey made the money fto petroleum and are now owners of cobalt Lthuiin batteries are ineffricutmt and dangerous but need cobalt. A monopoly again

Did you see the huge dairy farm destroyed in Texas nt hail now there are tons of toxic waste to clean up 80% not recyclable. Windmills break blades about four a year The composites are unryclable and get buried .Tge cold requires tons of fuel to melt ice on blades .The only profits are from those erecting the farms.

143 protocols on climate modifying systems and geoengeinering and yet jdiots cant see the agenda

Covid narrativewas tg ge first try they failed 7400 noe in jail . You did not hear? why 84000 media outlets printed

/ digital/ internet 84 people 8 corporations or 7 seven families . They own them all facts ho look it up dont use google it has paid several fines amounting to $11 billion in fines over the years for controlling agendas. The www is only 0,1% actually information

use science Gate or duck duck go

https://www.sciencealert.com/navigation-systems-finally-caught-up-with-the-mysteriously-north-pole-shift

https://www.pbs.org/newshour/science/the-earths-magnetic-north-pole-is-shifting-rapidly-so-what-will-happen-to-the-northern-lights

https://opentheword.org/2022/03/24/arctic-ice-cap-growing-again

https://eos.org/science-updates/new-perspectives-on-the-enigma-of-expanding-antarctic-sea-ice

https://www.thoughtco.com/does-oil-come-from-dinosaurs-1092003

https://newatlas.com/bioengineers-rebuilding-bacteria-to-produce-crude-oil/7723

https://www.gao.gov/products/gao-23-106261

https://www.downtoearth.org.in/news/environment/japanese-scientists-discover-plastic-eating-bacteria-53191

https://www.theguardian.com/environment/2023/sep/28/plastic-eating-bacteria-enzyme-recycling-waste

https://www.npr.org/2019/09/10/759376113/unfurling-the-waste-problem-caused-by-wind-energy

https://edition.cnn.com/2023/05/28/world/wind-turbine-recycling-climate-intl/index.html

https://yankeeinstitute.org/2020/12/03/department-of-public-health-concerned-about-pfas-in-solar-panels-near-drinking-water

https://yankeeinstitute.org/2020/12/03/department-of-public-health-concerned-about-pfas-in-solar-panels-near-drinking-water

https://www.dw.com/en/why-is-potential-new-cop28-head-also-boss-of-one-of-worlds-biggest-oil-companies/a-64403298

you been BBB

bullshot baffles brains

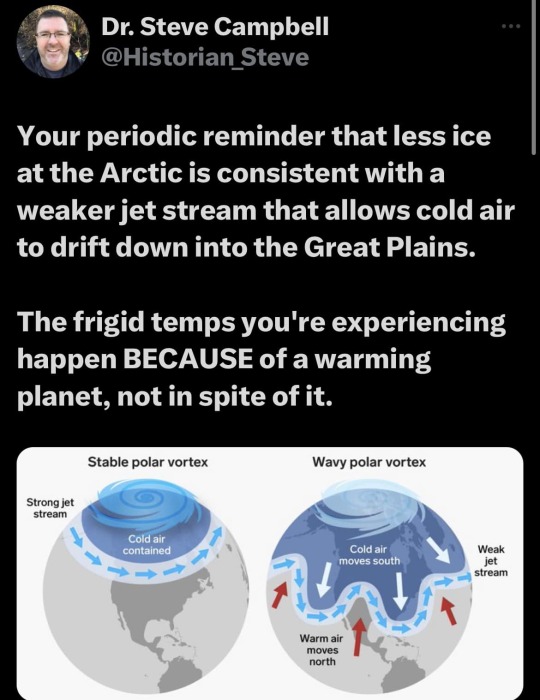

So many people do not understand the relationship between climate change and cold weather.

181K notes

·

View notes

Text

🛢️ Industrial Oil Cleaning System in India – Advanced Filtration & Purification by OilFilterMachineIndia.com

OilFilterMachineIndia.com offers cutting-edge Oil Cleaning Systems engineered for industrial performance and long-term reliability. Designed for transformer oil, hydraulic oil, turbine oil, and gear oil, our systems deliver precise and effective oil contamination removal to extend equipment life and improve plant efficiency.

Whether you need on-site solutions or continuous online oil cleaning systems in India, we provide versatile, customizable, and export-ready industrial oil filtration solutions trusted by OEMs, power plants, transformer facilities, and manufacturing units across the country.

⚙️ Our Expertise Covers:

Oil Cleaning System for industrial and energy sectors

High-performance Oil Cleaning System India with fast ROI

Turnkey Industrial Oil Filtration solutions

Real-time Oil Testing Equipment India for ISO-level cleanliness

Fully automated Online Oil Cleaning Systems India

Advanced Hydraulic Oil Filtration India for fluid power safety

Precision-driven Transformer Oil Filtration plants

Durable and efficient Centrifugal Oil Cleaners

Eco-friendly Oil Reclamation Units for reusing contaminated oil

Convenient On-Site Oil Testing India for operational assurance

Expert-built Oil Contamination Removal System for industries

Modular Oil Filtration System for multiple oil types

Transformer-specific Transformer Oil Cleaning System

Industry-ready Gear Oil Cleaning System

End-to-end Industrial Oil Filtration Solutions

Smart Oil Purification System with temperature & vacuum control

Sustainable, large-scale Industrial Oil Cleaning setups

Power-grade Turbine Oil Cleaning System for critical machinery

🌐 Why Choose OilFilterMachineIndia.com?

One-stop solution for industrial oil filtration and testing

Export-ready models with proven global performance

User-friendly design for easy on-site deployment

High reliability, low maintenance, and ISO 4406 standards compliance

Trusted by industrial clients across India and globally

📍 Based in India | Serving Global Industries 🔗 Learn more about our oil cleaning systems and request a quote: https://oilfiltermachineindia.com/oil-cleaning-system.html

#Oil Cleaning System#Oil Cleaning System India#Industrial Oil Filtration#Oil Testing Equipment India#Online Oil Cleaning Systems India#Hydraulic Oil Filtration India#Transformer Oil Filtration#Centrifugal Oil Cleaners#Oil Reclamation Units#On-Site Oil Testing India#Oil Contamination Removal System#Oil Filtration System#Transformer Oil Cleaning System#Gear Oil Cleaning System#Industrial Oil Filtration Solutions#Oil Purification System#Industrial Oil Cleaning#Turbine Oil Cleaning System

0 notes

Text

Unveiling the Power: Exploring the Importance of Transformer Oil Testing

Introduction

Importance of Oil Testing in Transformers

Oil testing serves as a diagnostic tool to evaluate the condition of the insulating oil used in transformers. By analyzing the oil’s composition and properties, experts can detect potential issues such as contamination, oxidation, or degradation. This enables early detection of problems, facilitating timely preventive maintenance or repairs.

Regular oil testing provides multiple advantages:Early Problem Detection:It helps identify abnormal conditions that might otherwise go unnoticed, reducing the risk of unexpected failures and costly downtime.Enhanced Decision-Making: It offers valuable insights into the overall health of the transformer, aiding in informed decision-making regarding maintenance and replacement strategies.

In conclusion, oil testing is an indispensable practice for ensuring the reliability and longevity of transformers. By leveraging oil analysis, companies can proactively address potential problems, optimize performance, and ultimately save significant costs in the long run.

Why is Oil Testing Important for Transformers?

Transformers are the backbone of modern electrical power systems, playing a crucial role in the efficient transmission and distribution of electricity. These vital components rely on insulating oil to maintain performance and longevity. The insulating oil not only acts as an electrical insulator but also helps dissipate heat generated during the transformer's operation. Over time, this oil can become contaminated, oxidized, or degraded, leading to issues that compromise the transformer’s functionality and may result in catastrophic failures.

Oil testing provides a comprehensive evaluation of the oil's condition, allowing for the early detection of potential issues. By analyzing the oil’s physical, chemical, and electrical properties, experts can identify abnormalities or changes that may indicate underlying problems within the transformer. This proactive approach enables timely preventive maintenance, repairs, or replacements, ultimately enhancing the transformer’s reliability and extending its service life.

Furthermore, oil testing is a critical component of a transformer’s health monitoring and maintenance program. By regularly assessing the oil’s condition, operators can make informed decisions about the transformer’s operational status and maintenance requirements. This helps minimize the risk of unexpected failures and ensures the reliable delivery of electricity to end-users.

Types of Tests Conducted in Oil Testing

Oil testing includes a variety of analytical procedures designed to evaluate the condition and properties of insulating oil in transformers. These tests can be categorized into the following key areas:

Physical Tests:Focus on the oil’s physical characteristics, such as color, appearance, viscosity, and dielectric strength. These parameters can indicate contamination, oxidation, or degradation of the oil.

Chemical Tests:Chemical analysis provides insights into the oil’s composition and the presence of contaminants or byproducts. Tests such as dissolved gas analysis (DGA), acid number measurement, and water content determination can help identify issues like overheating, partial discharges, or moisture presence.

Electrical Tests:Evaluate the oil’s electrical properties, such as dielectric breakdown voltage, power factor, and resistivity. These tests determine the oil’s ability to withstand electrical stress and provide early warning signs of potential insulation failures.

Understanding BDV Testing

The BDV test uses a specialized apparatus that gradually increases the voltage applied to the oil sample until breakdown occurs. A low BDV value indicates reduced insulating capacity due to contamination or deterioration. Regular BDV testing ensures that the oil maintains its dielectric strength, allowing the transformer to operate safely under various electrical loads. Maintaining a high BDV value allows transformers to operate more reliably and efficiently, minimizing the risk of insulation failure and unexpected downtime. As part of a comprehensive oil testing program, BDV testing provides a clear indication of the oil’s health and supports informed maintenance decisions.

Benefits of Regular Oil Testing

Regular oil testing offers a multitude of benefits for transformer owners and operators, making it an essential component of a comprehensive asset management strategy:

Early Problem Detection:Regular monitoring allows for early identification of potential issues like contamination, oxidation, or degradation, enabling timely preventive maintenance or corrective actions.

Optimization of Maintenance Strategies:Oil testing provides data that can be used to optimize the transformer’s maintenance schedule, ensuring efficient resource allocation and peak performance.

Improved Reliability and Lifespan:Addressing issues identified through oil testing helps extend the equipment’s lifespan and enhance its overall reliability, reducing the need for costly replacements.

Cost Savings:Regular oil testing can lead to significant cost savings by proactively addressing problems before they escalate, avoiding high expenses associated with emergency repairs, unplanned downtime, and premature equipment replacement.

Common Issues Detected Through Oil Testing

Oil testing is a powerful tool for identifying a wide range of issues that can affect the performance and longevity of transformers. Some common problems detected through oil analysis include:

Contamination: Foreign particles, such as dirt, moisture, or metal particles, can compromise the oil’s insulating properties, leading to increased electrical stress.

Oxidation:Over time, insulating oil can oxidize, forming sludge, varnish, and other byproducts that impair cooling and insulating capabilities.

Thermal Degradation:Excessive heat can break down the oil, forming gases and byproducts that indicate overheating or insulation failure.

Partial Discharges: Localized electrical discharges can be detected through oil testing, indicating insulation issues or maintenance needs.

Frequency of Oil Testing

The frequency of oil testing depends on the transformer’s size, age, and operating conditions. For smaller transformers, testing may be conducted annually or every two years. However, for larger, more critical transformers, more frequent testing, semi-annually or quarterly is typically recommended. Factors such as operating environment, load conditions, and any known issues can also influence testing frequency. For example, transformers in harsh environments or under high-stress conditions may require more frequent testing to ensure reliable performance.

Oil Testing Methods and Equipment

Oil testing for transformers involves various analytical techniques and specialized equipment, including:

Dissolved Gas Analysis (DGA):Measures dissolved gas concentrations in the oil, providing insights into potential issues like overheating, partial discharges, or arcing.

Dielectric Breakdown Voltage Testing: Assesses the oil’s ability to withstand electrical stress, a key indicator of its insulating performance.

Interfacial Tension (IFT) Measurement:Evaluates the oil’s stability at the water interface, with changes indicating contamination or oxidation.

Fourier Transform Infrared (FTIR) Spectroscopy: Identifies the chemical composition of transformer oil, including the presence of additives, contaminants, and degradation by-products.

How to Interpret Oil Testing Results

Interpreting oil testing results is critical for understanding the transformer’s condition and determining appropriate actions. Experienced professionals evaluate various parameters, comparing them to industry standards and historical data to identify abnormalities or trends that may indicate underlying issues. For example, increased concentrations of dissolved gases like hydrogen or acetylene may suggest partial discharges or overheating. Similarly, a decrease in dielectric breakdown voltage or an increase in acid number may indicate the need for oil filtration or replacement. By taking a holistic approach to interpreting oil testing data, professionals provide informed recommendations for maintenance, repairs, or replacement, ensuring reliable transformer operation.

Importance of Professional Oil Testing Services

Entrusting oil testing to professional service providers ensures the accuracy and reliability of results, as well as the effective implementation of maintenance strategies. Professional services offered:

Accurate and Reliable Results:Calibrated equipment and strict quality control protocols ensure accurate and reliable oil testing results.

Comprehensive Analysis and Interpretation:In-depth analysis and interpretation of data, identifying potential issues, and recommending corrective actions.

Compliance with Industry Standards:Adherence to ASTM (American Society for Testing and Materials) standards ensures quality testing procedures and reporting.

Customized Maintenance Strategies:Tailored maintenance strategies based on the specific needs and conditions of the transformer.

Conclusion

In the world of electrical power systems, the importance of oil testing for transformers cannot be overstated. As the backbone of modern power grids, transformers play a crucial role in delivering reliable electricity. Oil testing provides invaluable insights into the condition of a transformer’s insulating oil, enabling early detection of potential issues and facilitating timely maintenance actions. The benefits of regular oil testing include improved reliability, extended lifespan, and significant cost savings. By embracing this essential practice, companies can unlock the power of their transformers, ensuring they remain resilient, efficient, and ready to meet the evolving energy needs of the future.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#lube oil#oil analysis#lvdh#transformer oil#transformers#transformer oil cleaning#oil condition monitoring#flushing#chemcial cleaning#oil testing#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power industry#steel#metal#mining#oil#lube oil flushing

0 notes

Text

I've been thinking about this a lot lately. There's a show or movie called "Landman" with Billy Bob Thornton. I don't know anything about it beyond this one small clip I've seen. In the clip this woman who seems to be an environmentally conscious person and BBT are out in the scrub lands and BBT gives this speech about how petroleum (the substance that makes gas) is essential to life as we know it. He lists a bunch of products it is made into (stuff that woud make life difficult if it went away), then points out the wind turbines the woman seems interested in create a carbon footprint and implying they don't generate enough energy to offset that footprint.

And that argument sounds very compelling. BBT delivers it with a dispassionate calm, but stern tone like a disapproving parent talking to a child.

But then he keeps talking and shoots his argument in the proverbial fucking foot.

He starts talking about how we don't have the infrastructure to move the power from the wind turbines and solar panels to the people, and it would take 30 years to make a significant dent in that problem, and such a project would have a huge carbon footprint. Then says something about only having less than 200 years of petroleum anyway.

From my memory that's where the clip ends, with BBT walking away.

But the writers didn't listen to themselves and this story about President Carter illustrates my problem with his argument.

We could still try.

Imagine if Regan had not killed this idea. The 80's were 40 years ago. The internet was developed back then. Look where it is now. If we had people focused on engineering clean energy for 40 years, made it profitable for companies to invest in researching, where would it be? For all we know we might have eliminated our dependency on oil. We might still have tires and roads that require petroleum to be drilled for, but it might not be the big pollution problem it is.

This is my problem with society. We see problems that need fixing and if we can't fix them all in one fell swoop, we decode it's a dumb idea and give up. It boggles my mind.

I live in a midsized city in the U.S. We don't have a good public transportation system here. It's busses only right now. People howl and complain about how the bus doesn't go where they want to go, so a bill is passed to expand the routes and add more. Now people are howling and complaining about the construction clogging the roads. It's supposed to take 3 years and will greatly increase people's ability and willingness to use the bus. But this little inconvenience makes people scream about how they don't want it because they own a car. Well great, not all of us do. Maybe you could save money and have a nice night downtown and ride the bus rather than paying for gas and parking once or twice a year.

It benefits everyone to try and improve life. It might not work, but could we try?

74K notes

·

View notes

Text

What does industrial chemical cleaning actually involve?

At its core, industrial chemical cleaning is all about efficiency and safety. It uses chemicals—acids, alkalis, solvents, or detergents—to dissolve or dislodge stubborn residues that mechanical scrubbing or high-pressure water can’t touch.

These residues might include:

Mineral scale in heat exchangers

Oil sludge in pipelines

Rust in boiler tubes

Grease in food production plants

Biofilms in cooling towers

Anyone who’s dealt with an underperforming HVAC system or corroded machinery knows the frustration. Over time, build-up reduces operational efficiency, eats into energy budgets, and if left unchecked, can lead to full-blown shutdowns.

Why do businesses choose chemical cleaning over traditional methods?

Speed, thoroughness, and minimal disruption. Unlike physical cleaning, which might require disassembling parts or halting operations for days, chemical cleaning often happens in-situ—without dismantling anything.

That means:

Less downtime

Lower labour costs

Reduced risk of damaging equipment

More consistent cleaning results

It’s a bit like using vinegar and bicarb to clear a stubborn kitchen drain. The fizzy reaction cuts through gunk far more effectively than a wire hanger and elbow grease.

Which industries rely most heavily on industrial chemical cleaning?

Virtually every sector with complex machinery, heavy production, or strict hygiene requirements uses this service. But some industries lean on it harder than others:

Power Generation: To clean turbine blades, condensers, boilers.

Food & Beverage: For hygiene-critical equipment like pasteurisers and bottling lines.

Oil & Gas: To prevent corrosion, scale, and paraffin build-up in pipelines.

Manufacturing: For degreasing tools, tanks, and presses.

Pharmaceuticals: Where sterility is non-negotiable.

The more critical the process, the higher the stakes for cleaning—especially when safety, regulatory compliance, or millions in output are on the line.

What types of chemicals are used, and are they safe?

The cleaning agents used depend entirely on the type of residue and the surface being cleaned. Common categories include:

Acidic Cleaners (like citric or hydrochloric acid): Break down scale and rust.

Alkaline Cleaners (like sodium hydroxide): Cut through grease and organic build-up.

Solvents (like acetone or alcohol): Remove paints, oils, and adhesives.

Disinfectants & Biocides: Target bacteria, fungi, or biofilms.

Yes, these chemicals can be hazardous—but in the hands of trained technicians with proper PPE, monitoring systems, and waste handling protocols, they’re applied safely and responsibly. Think of it like chemotherapy for a machine: powerful, precise, and sometimes the only solution that works.

How do professionals manage the environmental impact?

Modern industrial cleaning isn’t a wild west of chemical dumping. In Australia, strict EPA and WorkSafe regulations guide every step—from chemical selection to effluent treatment.

Reputable providers also employ:

Closed-loop systems to contain and recycle chemicals

pH-neutralising units before wastewater disposal

HEPA filtration and air scrubbing for volatile substances

Some even use biodegradable or “green” formulations where possible, especially in industries like food production or agriculture.

Real-world example: A production plant on the brink

Here’s one that stuck with me. A food manufacturer in Victoria had a bottling line that kept jamming. Engineers tried adjusting pressure settings, swapping parts—no luck. Turns out, a thin film of sugary residue had built up inside the line. It wasn’t visible, but it slowed things just enough to throw off timing.

Enter a team of chemical cleaning experts. They flushed the line with a food-safe alkaline detergent, followed by a rinse and sanitisation cycle. The result? Immediate performance gains, fewer stoppages, and savings that dwarfed the cleaning cost.

Sometimes, the invisible is what costs you most.

How often should industrial chemical cleaning be done?

That depends on several factors:

Type of operation: Continuous vs. batch processing

Material handled: Is it sticky, corrosive, or prone to scaling?

Environmental conditions: Humidity, temperature, water hardness

Regulatory requirements: Especially for food or pharma facilities

Some sites clean quarterly. Others, like power stations, might schedule it annually or even based on condition-monitoring data (e.g., pressure differentials, flow rates). The smarter operators rely on predictive maintenance tools to decide the timing.

Who should carry it out?

This isn’t a DIY territory. Industrial chemical cleaning requires:

Specialist training in chemistry and handling procedures

Access to the right cleaning agents and safety equipment

Knowledge of your machinery and industry-specific standards

Cut corners here, and you risk not just damaging equipment but endangering your team or breaching compliance. That’s why firms often call in external providers with a proven track record and deep experience.

TL;DR: Industrial chemical cleaning uses precise chemical reactions to safely remove stubborn build-up from machines and surfaces in critical industries. It’s fast, efficient, and vital for keeping systems safe and productive.

And while it may not be the most glamorous job, it often prevents the kind of problems you don’t want to face at 3am on a production floor.

For businesses in Melbourne dealing with grime build-up, efficiency loss, or regulatory headaches, industrial cleaning professionals can provide a solution that works beneath the surface.

For more on best practices and safety frameworks, see this Safe Work Australia guideline.

0 notes

Text

India’s Aviation Fuel Terminals Market to Reach US$ 189.5 Mn by 2034

The Aviation Fuel Terminals Market in India is set to expand steadily over the next decade, driven by rising air travel, increased airport development, and the country’s strategic shift toward sustainability in aviation. According to recent market insights, the industry was valued at US$ 141.2 million in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 2.7%, reaching US$ 189.5 million by 2034.

Growth Drivers: Air Travel and Infrastructure

One of the most significant factors contributing to this growth is the sharp rise in both domestic and international air travel. India’s middle-class population is growing rapidly, making air travel more accessible than ever before. According to ICRA, domestic air passenger traffic is expected to reach 165–170 million in FY2025, with international passenger traffic having already surpassed pre-pandemic levels in 2023.

To support this surge, the Indian government and private players are investing heavily in aviation infrastructure. A projected US$ 11.88 billion is expected to be spent by 2025 on new airport development and modernization of existing facilities. These investments inherently increase demand for reliable and efficient aviation fuel terminals, which serve as a critical node in the aviation fuel supply chain.

Terminal Components and Their Role

An aviation fuel terminal typically includes:

A well-functioning fuel terminal ensures uninterrupted flight schedules, whereas insufficient fuel capacity could result in diversions or flight cancellations. Thus, ensuring operational continuity has become paramount for stakeholders, encouraging investments in terminal expansion and modernization.

Trends Transforming the Industry

A unique development in recent years is India’s increasing role as a refueling hub for international flights. Following the fuel crisis in Sri Lanka, South Indian airports such as Cochin, Chennai, and Thiruvananthapuram began facilitating technical landings for refueling. This change has not only improved ATF (aviation turbine fuel) sales in these regions but also reinforced India’s position as a regional fuel logistics hub.

Furthermore, sustainability is emerging as a core focus. The Indian aviation sector is making significant strides toward decarbonization. In 2023, Indian Oil Corporation partnered with LanzaJet Inc. and several domestic airlines to initiate Sustainable Aviation Fuel (SAF) production. SAF, derived from non-petroleum-based feedstocks such as used cooking oil, offers significant reductions in lifecycle carbon emissions.

The Government of India has also been encouraging the use of SAF to align with its broader environmental goals. This growing emphasis on alternative fuels is likely to reshape the fuel supply chain, including the design and operations of aviation fuel terminals.

Technology and Safety in High-Activity Zones

The aviation fuel terminals industry is also witnessing technological enhancements. In 2024, IndianOil Skytanking partnered with Netradyne to deploy the Driver•i fleet safety camera system across airport fueling operations. This AI-based system improves driver awareness and fleet safety in high-traffic zones around aircraft, aligning with DGCA safety regulations.

Additionally, many operators are implementing multi-camera functionality and real-time analytics to reduce risks during fueling operations, ensuring both personnel and aircraft safety.

Key Players and Strategic Moves

Several key players are shaping the aviation fuel terminals market in India. These include:

In February 2024, Cochin International Airport Limited (CIAL) teamed up with BPCL Kochi Refinery to set up a 1,000-kilowatt green hydrogen plant. This project is aimed at powering the airport’s vehicle fleet with clean energy, showcasing a move toward self-reliant and sustainable aviation infrastructure.

Market Segmentation Snapshot

The aviation fuel terminals market in India can be segmented by:

This segmentation highlights the diverse applications and ownership models across India’s growing aviation ecosystem.

Conclusion: Toward a Cleaner, More Connected Future

As India continues to invest in aviation infrastructure, the demand for efficient, safe, and sustainable aviation fuel terminals will continue to rise. The market’s trajectory reflects a broader transformation in how the country views air travel—not just as a convenience, but as a vital economic and environmental asset.

With strong government support, increased private participation, and a focus on alternative fuels and safety, India’s aviation fuel terminals market is well-positioned to play a pivotal role in shaping the future of air travel in the region.

0 notes

Text

Water also destroys computers, and anything that runs off electricity, so the odds that this cooling process involves dumping the water straight up directly onto the machines seems really, really unlikely. I would assume that water heat sinks involve pumping cold water through pipes in the machines, not literally dumping water on computers.

The ocean is very, very, very, very big. Also rising. If you consumed as much ocean water as there is drinkable water on the planet, you'd see an effect, sure, but you could literally remove billions of gallons of water from the ocean and have it be a proverbial "drop in the bucket". Since the tides are constantly sloshing the water in the ocean around, there will be no local "we drained a lot of water in this one coastal region so now the water is low there" effects; drain water in one region and the tide will fill it back in more or less instantly. It's the ocean, not a lake.

What you'd have to be careful about is the impact on fish and other sea life so they don't get sucked into the pipeline. Fine grates, maybe pumping in pulses so if a fish gets sucked against the grate the suction will be gone in a second so they can get out of there... maybe there are sounds or colors that could be employed underwater that would drive most sea life away. Don't put the entrance to the pipeline on the beach or directly on the sea bed; it should probably sit inside the water at a reasonably deep coastal level but with plenty of clearance, so as to not suck in sessile creatures who live on the bottom.

The pipeline itself would consume electricity -- the ocean's at the bottom of the gravity well of the planet's surface, you can't use gravity to passively pull the water back out. But by employing wave turbines, you can recapture a lot of the energy you put into pumping back out as power you can reuse. No such thing as a perpetual motion machine, but if by using seawater to fuel solar steam plants in places like deserts you can make back more energy than you had before, you've got a net positive outcome in terms of energy.

Issues to consider:

A salt water pipe breaking would be almost as toxic as an oil pipe breaking. And salt's corrosive to metal. You'd have to be careful what you made it out of, be constantly checking, and have baffles that will drop the moment there's a loss of local water pressure anywhere in the pipe, and a means of instantly and automatically stopping the pump if that happens. And protection of the pipeline to stop bad actors from deliberate sabotage.

Solar power plants can have an impact on the local environment if they block sun that plants and animals need. On the other hand, global warming suggests that what plants and animals need right now is a lot less sun overall, so creating areas of shade in places that don't have them might actually be good for the life in those places.

The whole system requires a lot of industries to cooperate. If solar steam plants or data centers dump their salt in giant piles in the desert rather than letting spice companies sell it as sea salt, this could be very bad for the environment. If rich people are allowed to fill their swimming pools with it, this has enormous political benefits for the pipeline because as soon as the rich feel entitled to it, they will make sure it stays working and stable, but then what happens if the data centers need more and more?

I don't pretend to have all the answers but I don't think any of the difficulties are insurmountable. Humans are using very, very little of the resource of ocean water, on a planetary basis... a resource we're getting more and more of as the seas rise, and as the heat dries up freshwater sources on land, we're going to need desalinization on a massive scale. Integrate that desalinization with industries that need to use water but it doesn't have to be fresh water, especially industries that could turn moving water or heated water into power in a way that's clean, and we could build a system that helps to solve multiple problems at once.

(BTW, this is not an issue of AI. This is an issue of data centers. The whole goddamn internet is to blame, not just AI, and even if AI collapsed and burned tomorrow we would still need to do something about cooling our data centers without using up drinkable water.)

63K notes

·

View notes

Text

Premier Cartridge Filters Manufacturer for Industrial Filtration | ClipOn

Cartridge Filters Manufacturer

Selecting the right cartridge filters manufacturer can significantly elevate the efficiency and reliability of air and liquid filtration systems in industrial settings. Cartridge filters are pleated elements designed for high-capacity particulate removal while maintaining low pressure drop. With ClipOn’s expertise in engineering and material selection, the products from a trusted cartridge filters manufacturer ensure top-tier performance in environments like mining, chemical processing, food production, and power generation.

Understanding Cartridge Filter Technology

A cartridge filters manufacturer focuses on designing pleated filter cartridges that maximize usable media surface area through criss-cross pleat patterns. This configuration enhances airflow, captures more debris, and reduces replacement frequency. ClipOn’s commitment to pleated cartridges provides durability and efficiency by optimizing dirt-holding capacity and maintaining airflow performance—ideal for high-dust or high-volume industrial applications .

Key Filter Media Options

Quality filter media selection is a hallmark of a leading cartridge filters manufacturer. ClipOn offers a range of media such as polypropylene, polyester, PPS, cellulose, and aramid, as well as PTFE membranes for submicron filtration. Polyester and polypropylene serve general applications effectively, while PPS resists high temperatures and corrosive chemicals. PTFE and aramid are used in aerospace, chemical, and food safety contexts where cleanliness and resilience are critical.

Air Filtration and Dust Collection

In industrial dust collection and HVAC systems, Cartridge Filters Manufacturer expertise is essential for ensuring clean air and adhering to environmental standards. ClipOn’s pleated cartridges are designed for both static and self-cleaning setups, such as pulse-jet dust collectors and turbine inlets. These cartridges perform efficiently even in dusty environments, helping reduce particulate emissions and improve equipment reliability in power plants, cement mills, and foundries .

Liquid Filtration Applications

Cartridge filters also play a pivotal role in liquid filtration systems. A proficient cartridge filters manufacturer provides filters that remove contaminants from oils, solvents, water, and food-grade liquids. ClipOn’s filter cartridges ensure high filtration consistency in chemical plants, food processing, wastewater treatment, and pharmaceutical production. Their precision and compatibility with liquid filter housings make them suitable for processes requiring sterility and purity .

Customization and Precision Manufacturing

A standout cartridge filters manufacturer offers customization to meet specific system demands. ClipOn provides custom sizes, pleat densities, end-cap options, and gasket materials. Their precision production techniques—such as ultrasonic welding, consistent pleat spacing, and leak-proof assembly—ensure filters perform optimally across pressure ranges with minimized bypass risk.

Quality Assurance and Compliance

Building confidence in filter performance requires stringent testing. ClipOn, known as a quality cartridge filters manufacturer, ensures that every filter undergoes burst strength, permeability, and retention testing. Compliance with ISO standards and certifications from associations like NAFA and ASHRAE demonstrate industry adherence. Detailed traceability and batch documentation ensure accountability—critical for healthcare, food production, and regulated sectors .

Benefits of Choosing a Specialist Manufacturer

Partnering with a top-tier cartridge filters manufacturer yields several benefits. Clients gain filters with high efficiency, extended service life, and reduced maintenance frequency. The cost savings from fewer replacements and lower energy consumption significantly impact operational expenditures. ClipOn’s filters also offer flexibility for system upgrades, align with sustainability goals, and maintain compliance with evolving emission and purity regulations.

Industry Success Stories

ClipOn’s filters have delivered measurable improvements in real-world setups. In one case, a chemical plant upgraded its inlet filtration to PTFE membrane cartridges sourced from ClipOn. The result was cleaner airflow, longer filter intervals, and smoother process operations. Another example is a food processing facility adopting FDA-grade polyester cartridges that improved fluid purity and reduced downtime—testament to the advantages of partnering with a quality cartridge filters manufacturer.

Innovations Driving the Next Generation

Innovation remains central to ClipOn’s role as a distinguished cartridge filters manufacturer. Their R&D initiatives include developing nanofiber-enhanced media for ultra-fine filtration, as well as RFID-enabled filters for inventory and lifecycle monitoring. These advancements enhance filtration efficiency, streamline maintenance, and support proactive service models, reinforcing ClipOn’s vision for the future of industrial filtration.

In conclusion, selecting the right cartridge filters manufacturer is more than a purchase—it's an investment in performance, reliability, and compliance across industrial sectors. ClipOn’s advanced pleated cartridges, diverse media options, customized design, and rigorous testing make them a trusted partner for filtration solutions. Their commitment to quality, innovation, and tailored support ensures their clients can achieve cleaner operations, lower costs, and sustainable growth. ClipOn exemplifies leadership in cartridge filtration technology, solidifying their reputation as an industry authority.

0 notes

Text

Renewable Energy: Powering a Cleaner, Smarter Future

In a world shadowed by climate challenges and environmental degradation, renewable energy stands as a bright and hopeful beacon. It’s more than a technological advancement—it’s a transformation of how we live, power our homes, and fuel our economies. From sunlight captured on rooftops to wind harvested from mountain ridges, renewable energy is reshaping the global landscape in ways that promise cleaner air, greater independence, and a sustainable future.

Unlike fossil fuels, which deplete and pollute, renewables regenerate and purify. Solar, wind, hydro, geothermal, and bioenergy sources are abundantly available and harness energy without scarring the planet. These energy solutions are now embedded in everything—from homes with solar panels to cars that recharge from the sun and wind farms that light up entire towns.